The amount of demand placed by our ever-increasing population, together with the increase of affluence and affordability make necessary an increase in industrial activities. As expected, the increase in demand for various products placed heavy demand on the raw materials to be extracted and manufactured with its pertinent demand in natural resources (water, land, mining activities and energy). Consequently, this produces emissions in the air and water, and an impact on the land, which has raised a serious concern about the future situation. Is there any way we can continue our development without needing the same requirement of natural resources or causing much less environmental impact?

It is clear that making decisions and solving problems in human-created systems, in a way in which its impact is minimum, is very complex. Often, design and decision making are motivated by one single objective, usually using less energy, higher profitability or optimizing the time of use. However, it is necessary to adopt an holistic approach, in which the different parts of the system are assessed simultaneously, considering different types of impact in each part of the process. The quantification of such environmental impacts can be addressed quite efficiently using LCA (Life Cycle Assessment).

What is LCA?

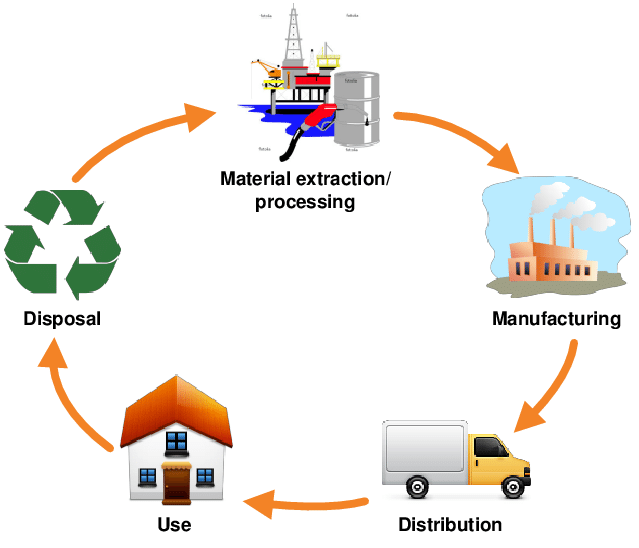

Every product or service, regardless its level of complexity, has a life cycle. Just as if we think about the biological life cycle, it has different stages. Starting with the extraction of the materials, the manufacturing, utilization and the disposal/closure.

LCA is a method that quantifies the environmental impacts of a product throughout its entire life cycle. What LCA does is to track those inputs and outputs of each stage and evaluate the potential impacts associated with them throughout the entire production, “from cradle to grave”.

And then interpret the results.

Let’s have a look at a simple example. A yogurt container made of plastic (exclude other parts of the container such as the aluminum lid). As it has been mentioned, it is made of plastic, that comes from crude oil, that has to be extracted and refined, then converted to plastic. Then it will be transported to a manufacturing plant, where it will become the container as we know it, and then it will be filled with yogurt, cooled down, distributed to the supermarket, consumed and eventually disposed. In order to perform a good LCA of the whole process, we need to answer the following questions: Where does this crude oil come from? How much do we need to produce the amount of plastic for a certain quantity of yogurt containers? What are the impacts associated with the fuel extraction, refinery, transport, manufacturing, distribution and disposal? LCA collects all the data necessary at each stage of the production and then studies the impact of each stage. This example of LCA was for just one material (the plastic of the yogurt container), but it can build up, as soon as we add complexity to the process and more materials.

How is LCA performed?

So basically, before performing a Life Cycle Assessment, it is needed a deep understanding of the process that is going to be assessed. We have to know how the whole process work, and ask ourselves the following questions (to start with):

– What are the stages?

– How much energy and water are needed?

– What materials are needed? How much? Where do they come from?

– What is it produced at each stage? How much of it?

– How do they contribute to the different environmental impacts?

Then an inventory analysis which consists of collecting all the data necessary is performed. If we were able to answer the above-mentioned questions, this process is smoother. Then we evaluate how the processes in the production chain contribute to different categories of environmental impact (global warming, acidification, ozone depletion, among others), and make an interpretation.

LCA acknowledges the environmental impacts in all the phases of the product’s life, and quantifies it. That makes it a very useful tool to compare different products, designs or services that perform the same function, and it allows us to see where along the product chain material and energy are most intensively consumed and waste produced. Therefore, the results from an LCA analysis can lead to setting environmental regulations or policies or writing environmental statements, identifying areas for improvement and collecting environmental data. All this favors the development of human-made systems that are more respectful to the environment and the use of natural resources.

Gema Amaya is an Environmental Engineer from Málaga (Spain) whose motivation for making the planet a better place to live has always led her steps. Throughout her training period and research career, she has acquired knowledge and skills in different fields of environmental engineering and management, implementing the concept of sustainable development to approach environmental problems.

She now would like to take a step further in the use of sustainability assessment in environmental problem solving, by taking an Early Stage Researcher position at UCL (University College of London), to work in the ESR15 InnovEOX project “Life-cycle assessment and cost analysis of emerging eAOP technologies” in which, under the supervision of Paola Lettieri (UCL)

InnovEOX Innovative Electrochemical OXidation Processes for the Removal and Analysis of micro-pollutants in water streams

InnovEOX Innovative Electrochemical OXidation Processes for the Removal and Analysis of micro-pollutants in water streams